By Greg Holbrook, EIT

Greg Nault, PE, SE, a representative and engineer from Ductal Engineering, a component of LafargeHolcim, presented to the Pittsburgh SEI Chapter last month on Ultra-High Performance Concrete (UHPC), most specifically it’s applications in Bridge Structures. He discussed many of the advantages and disadvantages of the material, as well as best practices and applications.

One of the most notable differences between conventional concrete and UHPC is the compressive strength. UHPC has a capacity upward of 25,000 psi compared to a range of 4,000 – 6,000 psi for conventional concrete. UHPC also has post-cracking tensile strength of 1,200 psi compared to 0 psi for conventional. In addition to holding higher loads, this is also a very useful feature to consider for accelerated construction - as typical design strengths are achieved very quickly with some products reaching 14,000 psi compressive strengths in as little as 12 hours.

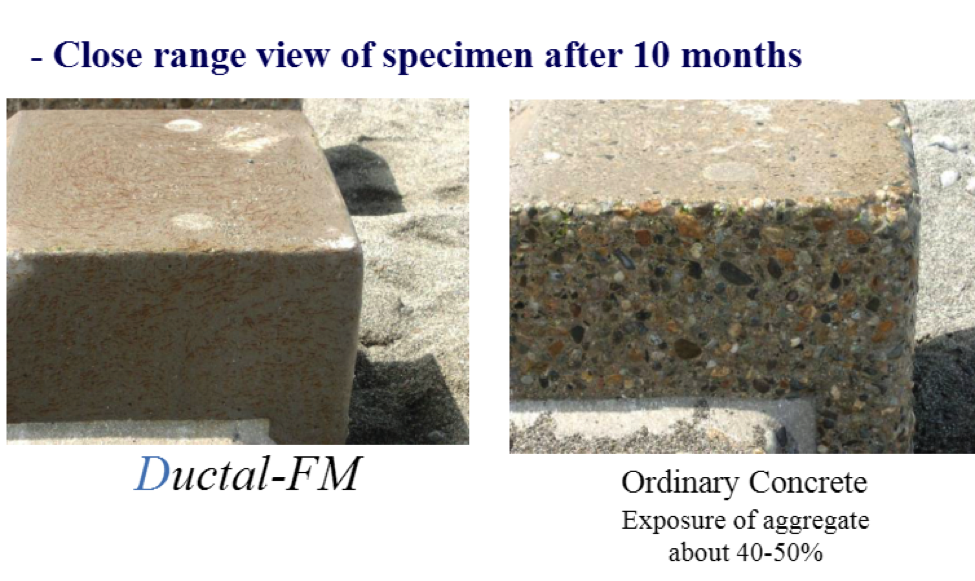

Another distinguishable advantage of the product is it’s durability due to a finer and denser pore structure as the cement hydrates. Its dense structure reduces permeability and potential corrosion of the reinforcement. Below is an image depicting two specimens, one of UHPC and one of conventional concrete, exposed to seawater in an abrasive environment for 10 months:

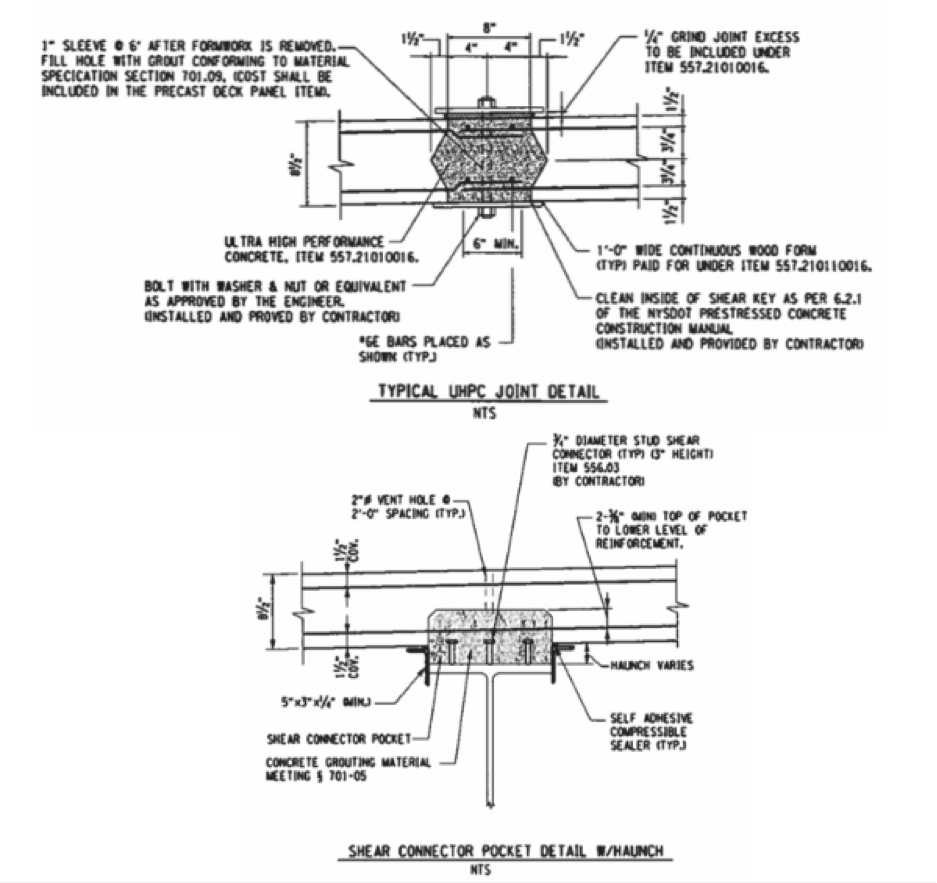

Another benefit of UHPC is a substantially reduced development length of reinforcement, which can be of great value in reducing the size of bridge joints. Additionally, this reduced development length can eliminate the need for hooked reinforcing bars in joints, which results in simpler detailing and easier construction methods. Typical joints and details for UHPC used in bridge joints are shown.

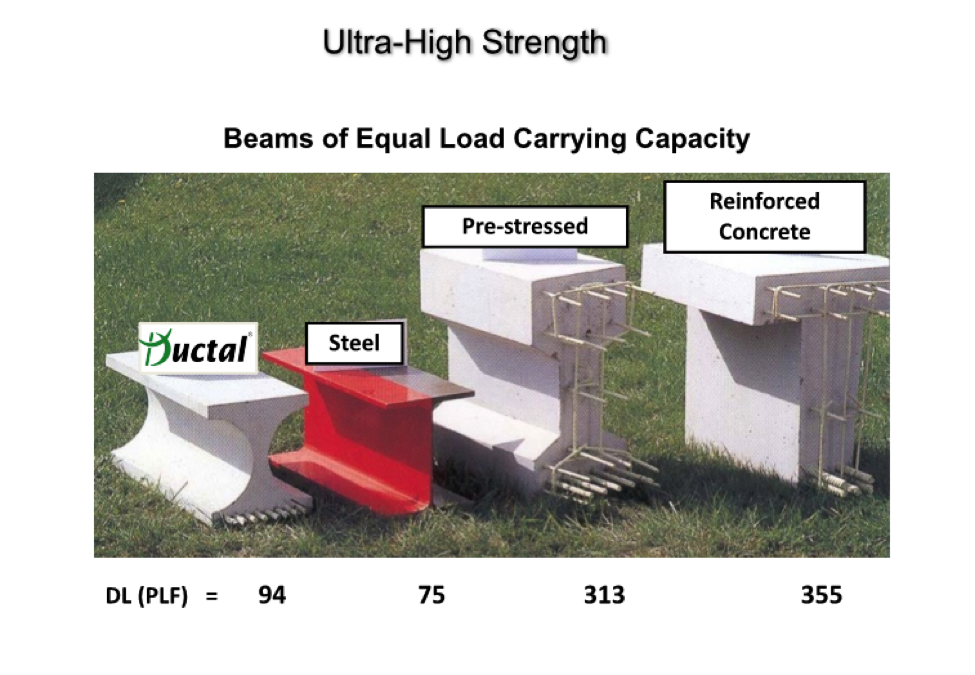

Due to its high compressive strength, UHPC structural components can be much smaller in size than their typical concrete (both precast or cast-in-place) counterparts. Here is a comparison of the different girders that can support the same loading:

While Ultra-High Performance Concrete does have many distinct advantages, it is important to account for some deterrents of the product. Most specifically the price of UHPC is substantially higher than conventional concrete in a direct volume comparison. However, it is important to note that less volume of UHPC is required for the same strength as typical concrete.

UHPC also requires batch mixing on-site and can only be done in small batches. Since it is a flowable material, it is necessary to be aware that large pours spanning long lengths of joints in bridge decks can create uplift pressure at the lower elevation points of the pour, which must be resisted by formwork. Specialty sub-contractors are typically necessary for this work.

The presentation served to bring awareness of Ultra-High Performance Concrete to structural engineers who may be considering this product as a potential option for upcoming projects. This is just an overview of some of the advantages and disadvantages of UHPC and it is important to contact vendors and engineers that are extremely knowledgeable in all the aspects of the product when determining its applicability for a project.

The Pittsburgh SEI Chapter is planning a presentation on the Accelerated Bridge Replacement of State Road 30 here in Pittsburgh, which used UHPC. This event will be held in the spring, and we encourage you to join us!